Description

Product Description

Ultrasonic sealing technology is a perfect solution for cosmetic or other liquid/semi-liquid product tube sealing. It can seal strongly with or without product stick on the sealing seam. Also the pattern and shape of the sealing seam is very much customizable.

Product Parameters

| Dimensions | 1100mm×800mm×1650mm |

Weight | 280kg |

| Power | 1.5KW |

| Voultage | 220V / 110V |

| Tube Diameter | 10-50mm |

| Tube Length | 50-220mm |

| Filling Range | 10-280ml |

| Compress Air Requirement | 0.4-0.8MPa |

| Machine Model | YTK-2005 |

Note: The parameter in this sheet is for reference only, some of the data may be different with different case.

Features

1. Easy to operate and maintain.

2. Automatic positioning, filling, welding, cutting and trimming, printing code in one time.

3. Stainless steel machine body, strong and beautiful looks,

4. Sealing mould can be customized according to customer requirements. Can seal many size of tubes.

5. Ultrasonic Sealing Machine power source for the pneumatic, working steady, not easy to damage, customers can rest assured use.

6. Ultrasonic frequency can meet international standard, no harmful to human being or environment

7. Can be work in time, not need wait the heat time .

Application

It can fill and seal the plastic tubes and plastic-aluminum laminated tubes. It is widely used in the cosmetic, medicine, lubricants, adhesive and shoe polish, food industries.

Working Procedures

1. Manually feeding the tubes

2. Automatic mark positioning (photoelectrical sensor)

3. Automatic dosing filling

4. Ultrasonic sealing

5. Tail sealing and pressing the batch, dates

6. Tail trimming

7. Automatic ejection

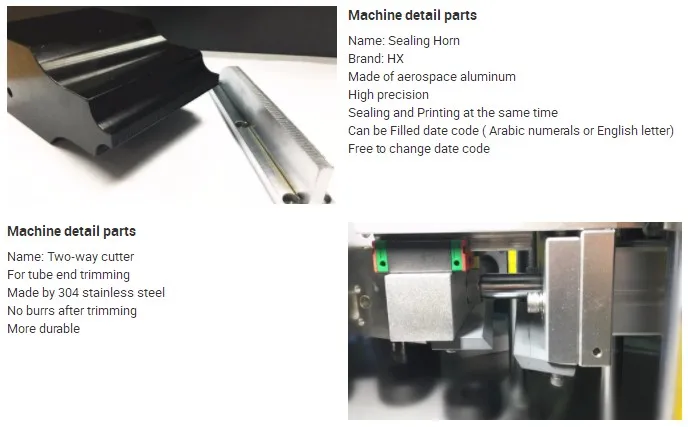

Detailed Images